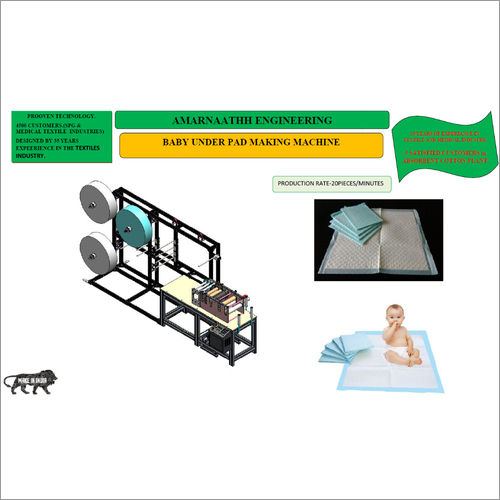

Disposable Underpad Making Machine

10000000.0 INR

Product Details:

- Product Type Other

- Power Source Electricity

- Operating Type Automatic

- Power 80 Horsepower (HP)

- Surface Treatment Painted

- Weight (kg) 100 Kilograms (kg)

- Click to view more

X

Disposable Underpad Making Machine Price And Quantity

- 10000000.0 INR

- 1 Unit

Disposable Underpad Making Machine Product Specifications

- Automatic

- 80 Horsepower (HP)

- Electricity

- Industrial

- 30 Kg/hr

- Painted

- 1 Year

- 100 Kilograms (kg)

- Other

Disposable Underpad Making Machine Trade Information

- 3 Unit Per Month

- 3 Months

- Yes

- Asia

Product Description

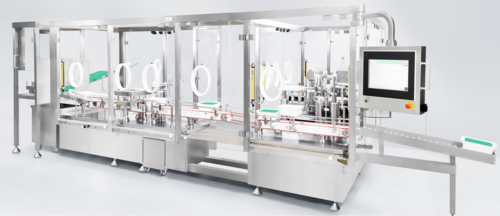

- Fully Automatic Operation: This machine is equipped with advanced automation technology, significantly reducing labor requirements. It performs cutting, folding, stacking, and packing tasks in a continuous and streamlined process.

- High-Speed Production: Designed for mass production, the machine operates at high speeds, ensuring a large output of high-quality disposable underpads with consistent precision and minimal waste.

- Multilayer Construction: The machine can create underpads with multiple layers, including a soft top layer, absorbent core (often made of fluff pulp and SAP), and a waterproof backing, typically using polyethylene (PE) film. These layers are bonded together efficiently to ensure durability and performance.

- Adjustable Size Options: The machine allows for customizable pad sizes, catering to different market requirements. Standard sizes include 30x45 cm, 60x90 cm, and 90x180 cm, but custom dimensions can be programmed based on user needs.

- Superior Quality Control: Built with precision sensors and quality control mechanisms, the machine ensures uniformity in each pad's thickness, absorption capacity, and overall construction. Defective products are automatically rejected during production.

- Advanced Material Feeding System: Automatic feeding of raw materials like non-woven fabrics, absorbent paper, PE film, and fluff pulp, ensuring a smooth and uninterrupted production flow.

- Easy Operation and User-Friendly Interface: The machine comes with a touchscreen control panel with user-friendly software that allows operators to set parameters such as pad size, production speed, and material usage with ease.

- Efficient Sealing and Cutting Mechanism: Equipped with heat-sealing and cutting systems that ensure clean edges, secure bonding, and product integrity, minimizing material wastage.

- Low Maintenance Design: The machine is designed for long-term reliability, with durable components and easy access for maintenance, reducing downtime and ensuring continuous operation.

- Safety Features: Integrated with safety guards, emergency stop buttons, and sensor-driven shutdown features to ensure operator safety during production.

Applications:

- Manufacturing of disposable underpads used in hospitals, nursing homes, and elder care facilities.

- Production of pet pads, baby changing pads, and bed protection sheets.

- Ideal for large-scale factories catering to medical and consumer hygiene industries.

Enter Buying Requirement Details