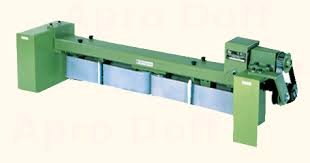

Lab Model Carding Machine

Product Details:

- Product Type Carding Machine

- Power Source Electricity

- Operating Type Automatic

- Power 180 Horsepower (HP)

- Surface Treatment Painted

- Usage & Applications Industrial

- Click to view more

Lab Model Carding Machine Price And Quantity

- 1 Unit

- 2500000.0 INR/Unit

Lab Model Carding Machine Product Specifications

- Automatic

- Carding Machine

- 180 Horsepower (HP)

- Electricity

- Painted

- Industrial

Lab Model Carding Machine Trade Information

- Cash Advance (CA)

- All India

Product Description

Surgical Cotton Carding Machine

A surgical cotton carding machine is a specialized piece of equipment used in the production of absorbent cotton for medical applications. This machine plays a vital role in transforming raw cotton fibers into a uniform, fluffy web, which is essential for ensuring the quality and effectiveness of surgical cotton products.

Key Features

1. Mechanical Operation

The carding machine uses a series of rotating drums and carding wires to open, clean, and align the cotton fibers. This mechanical process effectively separates and fluffs the fibers, removing impurities and ensuring uniformity.

2. Adjustable Settings

Many modern carding machines come with adjustable settings that allow operators to customize the processing speed, fiber density, and other parameters, ensuring optimal results for different types of cotton.

3. High Throughput

Designed for efficiency, these machines can process large quantities of cotton in a short time, making them essential for high-demand production environments.

4. Quality Control

The machine often includes features for monitoring and maintaining consistent quality, ensuring that the final product meets the stringent standards required for surgical use.

Applications

Surgical cotton carding machines are essential in the manufacturing process of various medical products, including:

- Absorbent surgical cotton for wound care

- Surgical dressings and pads

- Other healthcare materials that require high absorbency and softness

By ensuring that cotton fibers are properly carded, these machines contribute significantly to the overall quality and performance of surgical cotton, supporting healthcare providers in delivering safe and effective patient care.