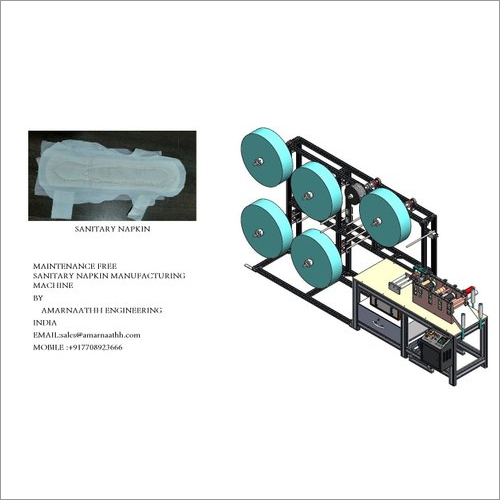

Sanitary Napkin Making Machine

800000.0 INR

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 440 Volt (v)

- Surface Treatment Painted

- Weight (kg) 4 Long Ton

- Click to view more

X

Sanitary Napkin Making Machine Price And Quantity

- 1 Nos

- 800000.0 INR

Sanitary Napkin Making Machine Product Specifications

- 1 year

- Automatic

- Painted

- PISTA GREEN

- 500 Kg/day

- Other

- 4 Long Ton

- Other

- 440 Volt (v)

- Electricity

Sanitary Napkin Making Machine Trade Information

- THOOTHUKUDI

- Cash Advance (CA)

- 3 Nos Per Month

- 3 Months

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

A Sanitary Napkin Making Machine is a specialized piece of equipment designed for the mass production of disposable sanitary pads or menstrual napkins. The machine automates the entire process, from feeding raw materials to packaging the finished products, ensuring that the sanitary napkins are produced quickly, hygienically, and consistently to meet market standards. These machines are widely used in manufacturing plants focused on producing feminine hygiene products.

Key Features and Process

1. Raw Material Feeding System:

- The machine includes automatic feeding units for different raw materials such as non-woven fabric (top sheet), absorbent cores (fluff pulp or SAP), tissue paper, polyethylene (PE) film (backsheet), release paper, and adhesive tapes. Each material is unwound from rolls and fed into the machine at precise intervals.

2. Absorbent Core Formation:

- The absorbent core is the most crucial part of the sanitary pad, responsible for absorbing and holding menstrual fluid. The machine creates the core using fluff pulp and super absorbent polymer (SAP). The SAP enhances the absorbency, while the fluff pulp provides bulk to retain fluid. These materials are evenly spread and shaped into a core of a specific thickness and length.

3. Non-Woven Top Sheet and Backsheet Application:

- The top sheet, made of soft non-woven fabric, is applied to the upper side of the pad, which comes in contact with the skin. The backsheet, typically made of polyethylene film, is placed on the bottom side of the pad to prevent any leakage. The non-woven fabric ensures comfort and breathability, while the PE film provides waterproofing.

4. Shaping and Cutting:

- The machine uses high-precision cutting tools to cut the pads into specific shapes and sizes based on the product design. This ensures that the sanitary napkins are ergonomic and fit the body comfortably. Various designs can be achieved by adjusting the cutting system to meet the needs of different markets (such as with or without wings).

5. Adhesive Application:

- A key feature of sanitary napkins is the adhesive used to attach the pad to underwear. The machine applies adhesive strips to the back of the pad and also places release paper over the adhesive to protect it until the pad is used. For pads with wings, adhesive is applied to both the central body and the wings.

Enter Buying Requirement Details