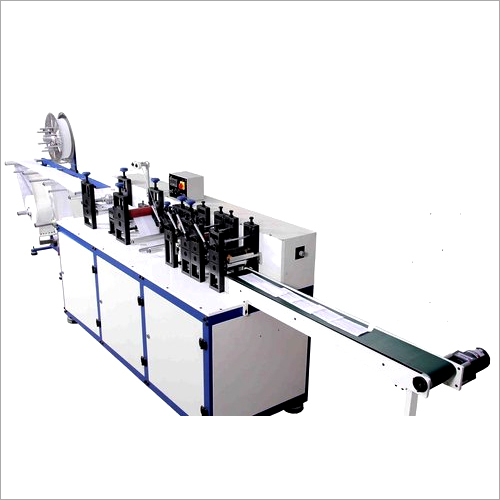

Face Mask Machine

Product Details:

Face Mask Machine Price And Quantity

- 1 Nos

- 850000.0 INR

Face Mask Machine Trade Information

- CHENNAI

- [ ' C a s h i n A d v a n c e ( C I D ) ' ]

- 3 Nos Per Month

- 3 Week

- Yes

- n e ] [ N o

- The packing details for cotton ball making machines involve packaging the finished cotton balls in a way that ensures they are protected during transportation, storage, and delivery while maintaining hygiene and quality. Below are the typical packing details for cotton balls produced by a cotton ball making machine: 1. Packing Materials: Inner Packaging: The cotton balls are usually packed in plastic bags made from polyethylene (PE) or polypropylene (PP). These bags are sealed to maintain cleanliness and prevent contamination. The bags often come in various sizes, depending on the quantity of cotton balls to be packed together. Outer Packaging: Once the cotton balls are packed into plastic bags, the bags are grouped into larger cartons or boxes for bulk shipping. These cartons are typically made from corrugated cardboard for strength and durability, ensuring the cotton balls are well-protected during transit. 2. Quantity per Package: Individual Pack: Typically, a set number of cotton balls, such as 50, 100, or 200, are packed in one bag. This number may vary depending on the requirements of the order or packaging specifications. Bulk Pack: Multiple bags of cotton balls (usually in the range of 10 to 50 bags) are packed together in a larger carton. For example, a carton might contain 10 bags of 100 cotton balls each, giving a total of 1,000 cotton balls per carton. Retail Packaging: For retail purposes, cotton balls may also be packed in smaller, consumer-friendly packages with clear labeling, often including information about the brand, product, and instructions for use. 3. Labeling: Product Information: Each individual bag and carton should have labels that provide essential information such as: Product type (Cotton Balls) Quantity (number of cotton balls per pack) Manufacturer details or brand name Batch or lot number Expiration or manufacturing date (if applicable) Instructions for storage or use Shipping Labels: The outer cartons will also have shipping labels that include information about the destination, the consignee, the weight, and any handling instructions (such as Keep dry or Fragile ). 4. Sealing and Hygiene: Sealing: To prevent contamination, cotton ball packages are usually sealed tightly. Plastic bags are heat-sealed or mechanically sealed to ensure they are secure and hygienic. Hygiene: As cotton balls are used for medical, cosmetic, or personal care applications, strict hygiene standards must be followed during packaging. This includes working in clean environments and using gloves or masks to handle the cotton balls during packaging.

- [ ]

- l I n d i [ ' A l a ' ]

Product Description

A cotton ball making machine is an automated machine used in the textile industry to produce cotton balls, which are widely used in medical, cosmetic, and household applications. These machines are designed to efficiently convert raw cotton into soft, round cotton balls in a highly automated process, ensuring consistency in size, shape, and quality.

Key Components and Working Process of a Cotton Ball Making Machine:

-

Raw Cotton Feeding: The process begins by feeding raw cotton into the machine. The cotton is usually in the form of fluffy, loose fibers. The machine uses a feeder system to bring the cotton into the production area.

-

Opening and Cleaning: Before forming cotton balls, the raw cotton is passed through an opening system that loosens and separates the fibers. This step helps remove impurities, dust, and other contaminants, ensuring the cotton is clean and ready for further processing.

-

Carding: In this stage, the cotton fibers are carded, which means they are passed through a set of rotating rollers and brushes that align the fibers in a uniform direction. This step creates a smooth, fluffy sheet or web of cotton.

-

Forming Cotton Balls: The cotton web or sheet is then fed into a rolling mechanism, which forms the cotton into small, round balls. The machine automatically shapes the cotton into uniform, soft, and compact balls.

-

Winding and Compression: Some machines use a winding mechanism to further compress and form the cotton balls, ensuring they are tightly packed and will maintain their shape. The balls are wound or pressed into the correct size.