Disposable Syringe Injection Making Machine

30000000.0 आईएनआर

उत्पाद विवरण:

- प्रॉडक्ट टाइप

- टेक्नोलॉजी

- पावर सोर्स

- ऑपरेटिंग टाइप

- पावर वोल्ट (v)

- सतह का उपचार

- आयाम (एल* डब्ल्यू* एच) यार्ड

- Click to view more

X

मूल्य और मात्रा

- 1

उत्पाद की विशेषताएं

- पीसीएस/मिन

- टन

- PISTA GREEN

- वोल्ट (v)

- यार्ड

व्यापार सूचना

- THOOTHUKUDI

- प्रति महीने

- महीने

- Yes

उत्पाद विवरण

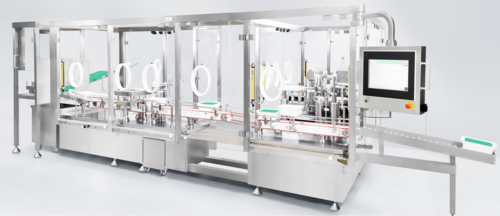

A Syringe Making Machine is a specialized piece of industrial equipment used for the mass production of disposable medical syringes. This machine automates the entire process, from molding the components to assembling, sterilizing, and packaging the syringes. The production is highly precise, ensuring that each syringe meets medical-grade standards for safety, hygiene, and functionality. These machines are typically used in large-scale manufacturing environments, supplying syringes to hospitals, clinics, and medical supply companies.

Key Features and Process:

1. Injection Molding Unit:

- The core of the syringe making machine is the injection molding unit, where the plastic components of the syringe barrel, plunger, and needle hub are produced. The machine uses high-grade plastic (typically polypropylene) pellets, which are melted and injected into precision molds. Each mold forms the syringe components with high accuracy, ensuring uniformity in size and shape.

2. Barrel and Plunger Formation:

- Barrel: The clear, cylindrical body of the syringe where fluids are drawn or injected is formed in this step. It is calibrated with precise volume markings for accurate dosage measurement.

- Plunger: The plunger is the part that moves within the barrel to draw or push the fluid. It is also molded, ensuring smooth motion within the barrel for ease of use.

3. Needle Hub Molding:

- The needle hub, which holds the metal needle in place and connects it to the syringe barrel, is also molded in the machine. It is designed to securely hold the needle and prevent leakage during use.

4. Needle Attachment (for Needle-Fixed Syringes):

- For needle-fixed syringes, the machine automatically attaches the metal needle to the molded hub. Needles are typically made of stainless steel and are assembled with the hub using precision equipment to ensure alignment and strength.

5. Rubber Gasket Formation:

- The rubber gasket is placed at the end of the plunger to create an airtight seal inside the barrel, allowing for the smooth drawing and expelling of fluids. The machine either molds the gasket separately or integrates it during the assembly process.

क्रय आवश्यकता विवरण दर्ज करें